With the structural adjustment and upgrading of the automobile industry, the demand for aluminum alloy wheels is increasing. Based on the production of die-cast aluminum alloy wheel hubs, it has achieved leapfrog development. During the trial production of forged aluminum alloy wheel hubs, a large number of bubbles appeared on the surface of the wheel hubs. The bubbles were scanned by electronic probes for qualitative and quantitative analysis.

The morphology of bubbles on the surface of forged aluminum alloy wheel hubs has three manifestations.

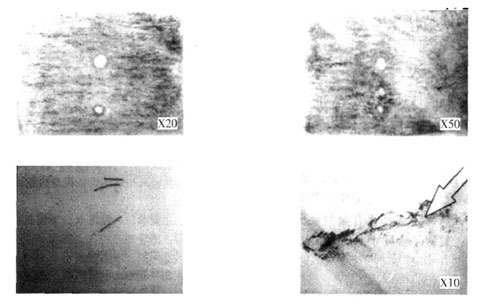

1.Round bubbles on the surface of forged aluminum alloy wheels

2. Oval bubbles on the surface of forged aluminum alloy wheels

3. Needle-shaped strip bubbles on the surface of forged aluminum alloy wheels

4. Air bubble industry with long cracks on the surface of forged aluminum alloy wheels

Causes of bubbles on the surface of forged aluminum alloy wheel hubs and solutions technical engineering

(1) Round and elliptical bubbles (as shown in Figure 1 and Box 2). The bubble size is about l~6mm, the size is uneven, the distribution is uneven, and the surface is a closed bubble with a complete convex surface.

(2) Needle-shaped strip bubbles (as shown in Figure 3). The size is about 2 to 8 ram, and the number is sparse, with closed bubbles with strips on the surface. The above two kinds of bubbles mostly appear on the inner rim and sometimes on the outer surface of the spokes. These two kinds of bubbles do not appear in the process of blank rotating flattening, hot die forging and cold spinning, and only appear after solution and aging heat treatment.

(3) Long cracked bubbles (shown in Figure 4). The size is about 10~30ram~50~1|0ram. This is a typical open bubble. There are obvious cracks on the surface of the bubble. A heavy skin interlayer can be found, and the interlayer is filled with black material. The bubble direction is consistent with the deformation direction, and is distributed in a certain place of the inner rim and the outer rim. Such bubbles will be found after hot die forging or cold spinning. 2 Cause analysis of air bubbles on the surface of forged aluminum alloy wheel hubs

2.1 The solid ammonia measurement of the blank ingot used for the forged aluminum alloy wheel hub In order to find out the gas source in the bubble of the wheel hub, 7 samples of the blank ingot were taken for solid hydrogen measurement. The test results are shown in Table 1. Table 1 Solid ingot hydrogen measurement analysis sample number 3#4#5#04#05#06#07# The hydrogen content of 0.120.130.130.180.250.180.17mL°§100g can be obtained from Table 1. see. Among the 7 samples: 4 samples of 3#, 4#, 5#, 07# contain hydrogen less than 0.18mL/100g (the alloy hydrogen content standard), 04#, 06# two The hydrogen content of the sample is the upper limit of the standard, and the hydrogen content of the 05# sample exceeds the standard, indicating that there is a high hydrogen content in the rough ingot.

2.2 Porosity and porosity inspection of blank ingots The low-magnification inspection of 7 blank ingot samples showed that no porosity and porosity defects were observed. Through high-power microscope and electron probe scanning, defects such as subcutaneous looseness and cracks were detected. The results are shown in Table 2. It can be seen from Table 2 that the blank ingot has no pores and slag inclusion. 3# sample has subcutaneous cracks, 05# sample has subcutaneous looseness.

2.3 Qualitative and Quantitative Analysis of the Composition of the Air Bubbles Scan the surface of the forged aluminum alloy wheel hub with an electronic probe to scan the surface of the air bubbles. 2 The surface texture of the rough ingot is tested. Cortex depth (including chill layer, 0.5+2.00.3+0.5+coarse crystal layer)/22.02.0mm subcutaneous looseness slight slight slight slight slight slight slight slight looseness no no no no no no no nothing Metal No No No No No No No No Inclusions Skin Crack Width 1.5mm No No No No No No No Length 3mm Table 3 Forged Aluminum Wheel Hub Open Bubble Electronic Probe Scanning and Detection of Chemical Composition in the Bubble (mass fraction/% ) Sample number CONaMgAICIKCaSBe1#72.42l2.830.050.3l10.940.330.141.180_270.184#613520.203.40.256.210363.012.451391.280.18 Matrix 0.798.960. The skin layer of 355# was traced at 0.4199.110.48, and its constituent elements were analyzed qualitatively and quantitatively. The results are shown in Table 3. It can be seen from Table 3 that there are a large amount of carbon and beryllium in the substances contained in the bubbles. After chemical analysis of light diesel oil, refining agent, launder plate, and graphite lubricant used on site, the results showed that the substances contained in the bubbles were consistent with graphite lubricant.

2.4 Bubble detection and analysis results (1) The root cause of bubbles on the surface of the forged aluminum alloy wheel hub is hydrogen and graphite lubricant (2) The type of bubbles on the surface of the forged aluminum alloy wheel hub is a surface precipitation type bubble caused by hydrogen; The other is a surface pressure type bubble formed by mixing lubricant. (3) Formation mechanism of bubbles on the surface of forged aluminum alloy. Formation mechanism of precipitation-type bubbles: In the process of forging and spinning hot working deformation of blank ingots with subcutaneous looseness, hydrogen in the loose layer will precipitate and accumulate to form metal stratification. Metal when heated.

Conclusion: (1) There are two main types of bubbles on the surface of forged aluminum alloy wheel hubs: one is a closed bubble. The other is an open bubble. Closed-shaped bubbles are caused by hydrogen, and belong to gas evolution bubbles. Open-shaped bubbles are caused by the pressure of lubricant, also called pressure-shaped bubbles.

(2) Reducing the hydrogen content of the melt, improving the melting and casting process, and making the thickness of the surface of the ingot ingot thinner are the key to solving the bubble problem.

(3) The solution to air bubbles on the surface of forged aluminum alloy wheel hubs is to use scientific means to find out where the problem lies, and to take effective measures in a targeted manner. Practice has proved that bubbles can be effectively controlled.

JHM WHEELS JHM INC