Motorcycle wheels and tires are assembled in two states, one with inner tube and the other with tubeless tire. The valve core hole of the inner tube hub is directly penetrated, while the valve core hole of the tubeless wheel hub is a stepped hole. The wall thickness of the tubeless tyre valve core hole directly affects the assemblability of the valve core and the safety of subsequent driving. Affected by blank deformation, eccentricity, etc., the wall thickness of the valve core hole is difficult to control. We design a special drilling machine fixture to increase the contact area between the reference surface of the part and the fixture to ensure the consistency of the wall thickness of the drilled valve core hole.

The wheel hub is a safety component in the entire motorcycle and requires high dimensional accuracy. The hub is mainly composed of three parts: the drum (consisting of the shaft core and the drum), the spokes, and the wheel. The material is aluminum alloy. The diameter of the hub is generally between 280 and 500 mm. The wall thickness of the tubeless valve core hole is required to be ¡À0.5 mm. Ideally, it is necessary to ensure that the concentricity between the hub center and the wheel is within 1 mm in order to meet the accuracy requirements.

In the actual production process, due to the many manufacturing processes of aluminum alloy wheels, from the first casting to drilling the valve core hole, it needs to go through casting, cutting and pouring riser, punching center hole, deburring, heat treatment, grinding, shot blasting, and machining. One air tightness test one drilling the valve core hole. In these technological processes, many factors such as casting mold deformation, heat treatment deformation, machining deviation, etc., affect the coaxiality of the axle core and the wheel vehicle to varying degrees. This makes it difficult to control the wall thickness of the valve core hole. How to reduce the factors that affect the wall thickness deviation of the valve core hole.

1 Reason analysis

Because the thickness of the tubeless valve hole directly affects the performance after assembly, the accuracy requirements are high. In actual production, through on-site investigation, the processing qualification rate is only 92.65%. In order to improve the processing quality and ensure the safety of use, we have set up a research team to conduct a preliminary analysis of this problem with QC methods and quality management tools.

First, we summarize and discuss various influencing factors through on-site analysis. After many on-site analysis and test demonstrations, the main influencing factors are the eccentric deformation of the product and the uneven force of the workers when drilling.

From the above test results:

a) The overall pass rate of bad blanks is 93.1%, and the position is irregular, and the cumulative error between the processes has a greater impact on the positioning and size control of the drill valve core hole.

b) The average pass rate of drilling valve core holes is 98.3%, excluding the influence of casting deformation, heat treatment deformation and machining eccentricity. We found that during the drilling process, the operation method is manual production, and the uneven force of the workers when drilling has a direct impact on the processing results.

Through the analysis of the above test results, in actual production, we found that the pass rate of each related process cannot be controlled to reach 100%, and there are cross-effects. With the current drilling technology, the above-mentioned process eliminates deformation and other factors to ensure the design of drilling thickness , Is very difficult, and because the drilling is manual production, the skills are not synchronized, resulting in fluctuations in product quality.

In view of the above situation, we improved the tooling design so that it was not affected by the deformation of the previous processes, and carried out the idea of automatic transformation to improve the pass rate of the core hole thickness of the drill valve.

2 Scheme improvement

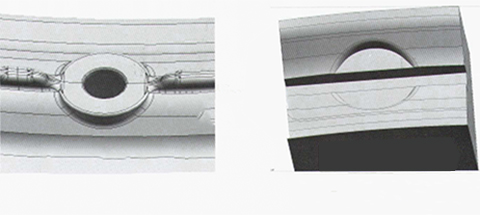

a) Through theoretical analysis and practice, the original valve core tooling has been redesigned: the original shaft hole positioning shaft and gear lever positioning plus pull claw clamping and fixing are changed to valve core hole boss backing positioning plus pulling claw Clamp and fix. Eliminate the influencing factors of deformation and eccentricity by changing the job positioning position.

After the improvement of the valve core hole positioning tooling described above, since the processing positioning surface is directly the lower plane of the valve core hole, the datum is fixed and unchanged, and the depth of the drill bit is adjusted to ensure that the valve core hole wall thickness is consistent.

b) After the new tooling design is used, it effectively avoids product deformation and poor processing caused by eccentricity, ensures the consistency of product processing quality, and lays a solid foundation for processing automation. We replaced the original manual with a CNC drilling machine Vertical drilling realizes automated production and eliminates the impact of uneven force on product quality caused by unsynchronized employee skills.

c) Effectiveness verification: We randomly selected 300 pieces from the site to drill the valve core holes, 295 pieces were qualified, and the pass rate was 98.3%. The unqualified products were analyzed, and the concentricity, eccentricity and wheel of several products with excessive wall thickness were analyzed. The roundness of the car is within the required range. It can be seen that this clamping method can effectively avoid the effects of product concentricity, eccentricity and wheel roundness.

But what caused these 5 defects? The analysis and many tests have proved that due to the insufficient assembly clearance and bearing capacity of the connecting elbow and the base for the positioning of the valve core hole boss, the positioning tooling has been improved. The valve core hole boss is used for backing positioning and vertical pressing and fixing. Replace the assembly of the elbow and the base with a fixed plate, as shown in Figure 5.

3 Final verification

This tooling is firmly fixed, has no deformation, and is not affected by pressure. The tooling is designed and processed according to the product structure, and its positioning surface is completely fitted to the product processing part, so that the influence of external factors is minimized.

The improved effect was finally verified. A summary of 400 random inspections of valve core holes from the site is shown in Table 2.

It can be seen from the test results that the pass rate of the improved tooling was 99.75%, and the reason for the defective one was that the aluminum chips in the tooling were not cleaned up during processing. So far, our improvement has met the design requirements.

4 Conclusion

In the production process of aluminum alloy wheels, the diameter of the wheel itself is large, and the process flow is many. Uncontrollable eccentricity and deformation will occur in the processes of rough casting, heat treatment, and machining, which will affect the subsequent processing. Improved tooling by drilling the valve core hole , Optimize the positioning reference, effectively eliminate the influence of the bad deformation of the product on the process of drilling the valve core hole. At the same time, in the actual operation process, it is necessary to ensure that there is no aluminum chip on the positioning tool of the valve core boss, and there are no coating scars, particles and bumps on the boss of the hub valve core hole, so as to effectively ensure that the wall thickness of the valve core hole is within the tolerance range. Inside.

JHM WHEELS JHM INC