In order to improve the accuracy of real-time monitoring of aluminum alloy wheel low pressure casting mold temperature, reduce mold preparation time, and reduce mold temperature monitoring costs, the study is optimized on the traditional mold temperature monitoring system, and the appropriate temperature measuring thermocouple is selected to study the efficient thermocouple Installation plan. Practice has shown that the plug-in installation scheme of K-type armored thermocouple can not only obtain high-precision temperature measurement, but also greatly shorten the mold preparation cycle and effectively reduce the production cost.

The mold temperature during the casting of aluminum alloy automobile wheels has a decisive influence on the casting process. Too high or too low temperature will not be conducive to the forming and solidification of the product, thereby affecting the quality of the product. How to efficiently monitor the mold temperature in real time, and thus realize the intelligent control of the mold temperature in real time, is a big problem in the foundry industry.

As the automotive industry¡¯s demand for aluminum alloy wheels continues to increase, vehicle manufacturers have increasingly higher requirements for the casting quality of aluminum alloy wheels. In order to comply with the market and improve quality, our company started the mold temperature monitoring project in 2014. Many experiments and researches on mold temperature detection methods have successfully developed a high-efficiency, low-cost, and practical detection method, which has laid a solid foundation for the industry's mold temperature control project research and is a milestone.

1. Determination of the measurement site

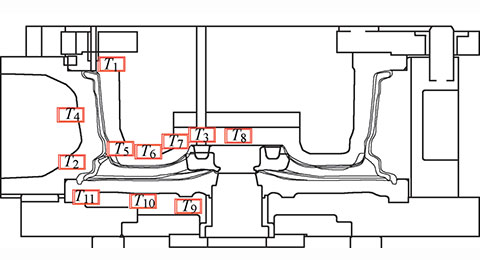

The real-time monitoring of the mold temperature has a very important relationship with the determination of the temperature measurement point. In the determination of temperature measurement points, 11 measurement points were initially selected according to the structure of the hub product and the characteristics of the mold structure, as shown in Figure 1. Taking into account the processing difficulty of the measuring points, the sequential solidification and cooling of the castings, and the versatility of the temperature measuring points, three positions T 1, T 2 and T 3 are finally selected.

2. The choice of thermocouple There are various types of thermocouples on the market. Common thermocouples include platinum-rhodium 10-platinum thermocouple (graduation number S, also called single platinum-rhodium thermocouple); platinum-rhodium 13-platinum thermocouple (graduation

The number is R, also called single platinum rhodium thermocouple);

Conclusion

For the castings of the transmission back cover shell, because of the large number of hot spots and scattered, and most of the wall thickness is thin, it is difficult to form an effective feeding channel, so the use of multi-gate technology is a more suitable solution, in which the distribution of each gate Location is the core element of the plan. In addition, for 20181228 oil channel sand cores that are difficult to be fixed by metal, the bonded core assembly is a safe solution that can effectively ensure the position of the sand core.

The above casting process development process shows that with the help of modern computer three-dimensional graphics CAD technology, it can help to quickly analyze the structure of the casting and find out the parts that are prone to defects in the casting. The CAE simulation analysis technology of the computer casting process can effectively verify the reliability of the process plan, find and improve the missing points of the plan, replace the traditional process trial and error methods, and save the trial production cycle and cost to the greatest extent.

JHM WHEELS JHM INC