In recent years, Chinese automobile market has matured, and the development potential of the domestic after-sales market has gradually been released. The status of the accessory business in the future development strategy of vehicle companies has gradually increased. Consumers have increased their styling design requirements under the influence of individual demand. Diverse and individual aluminum alloy wheel design has also become one of the means to enrich the automotive market and increase market competitiveness. Driven by new energy and intelligent technology, the automotive industry itself is also undergoing a revolution, whether it is products, technologies or models that are undergoing a complete change. In the current information age, computer technology has widely penetrated into all areas of the design world, and the parameterization technology in computer technology has gradually developed and matured, providing many new methods and paths for modeling design. Nowadays, there are many design fields. Many successful application cases. In this article, in order to make the shape of the aluminum alloy wheel consistent with the overall design style of the car, the personalized design adopts an objective personalized customization method, rather than subjective customization by consumers.

1. Parametric design method

With the development of science and technology, the application of computer technology has extensively and profoundly affected the manufacturing and design industries. As a branch of computer technology, parametric technology has brought a huge leap and update to the design industry, becoming a design revolution based on technology update. Initially, parameterization was applied as a parametric technology to the digitalization of industrial production processes. With the development of related production conditions and digital technology, the architectural design industry took the lead in applying parametric technology to the design process. This is a revolutionary design innovation , Formed an innovative design method, namely the parametric design method. The core of the parametric design method is the correlation and logic between each element, that is, an initial parameter model is formed in which each element is connected to the design result. This type of parameter model is easy to operate and can continuously modify the design element parameters, which can help the design. The designer quickly modified the model to form a variety of different design schemes. Generally speaking, the parametric design method is composed of three key processes of finding the parameters of design elements, setting the change rules of the unit shape, and choosing which software to model. In recent years, parametric design methods have been gradually applied to car design. Whether it is car body exterior design, interior design or aluminum alloy wheel design, you can see parameterization, which provides a good for the development of car design Help, but also brings new challenges. Aluminum alloy wheels are an indispensable part of automobile design. How to apply parametric design methods to the design of automobile aluminum alloy wheels and to match the overall design style of the automobile is the problem to be discussed in this article.

2. Current status of automotive parametric design applications under individual requirements

The mass-produced products in the modern manufacturing system can no longer meet people's spiritual, cultural, emotional, and individual needs. Parametric design, as a design direction of personalized design, forms a unique appearance through regular unit shape changes, which can become a unique feature of the product. In recent years, there have been more and more cases of parametric design applied to automobile design, such as the concept car Vision; Next; 100 released by BMW in March 2016, which is the beginning of the application of parametric design methods in automobile design. The shape and the shape around the wheel pack adopt a movable parametric structure, which is in sharp contrast with the traditional car design mode. The body is full of technology and futuristic; the concept car EZ-ULTIMO released by Renault in 2018, the area above the waistline adopts diamond parameters Modified decoration; the 2019 DS concept car XE-Tense, the asymmetric design of the body, and the triangular scaly parametric headlights have a great sense of design; the Audi concept car AI released in 2019: ME and Kia concept car Imagine; By; KIA , The car body design has added parameterization to increase its brand recognition. Under the influence of parametric design, some designers began to apply parametric design methods to the design of automotive aluminum alloy wheels. The application of parametric design in the appearance design of automotive aluminum alloy wheels can be divided into two types: parametric engineering design direction application and parametric form design. Among them, parametric engineering design direction has been applied to automobile design very early, and its development is relatively mature. The design of parametric shapes has only been applied in the design process of aluminum alloy wheels in recent years. It is mainly to design the skin of the aluminum alloy wheel shape, and add regularly arranged unit shapes to the skin to form a unique texture feature.

At this stage, domestic and foreign aluminum alloy wheel personalized customization channels usually use professional customization websites. Consumers can only customize materials, colors and sizes, but not form customization; consumers directly participate in personalized aluminum wheel customization On the one hand, there is still no suitable approach, method, and theory-based design process. The integration of parametric design methods in the shape design of automotive aluminum alloy wheels requires continuous exploration in the design community and gradually adjust the methods to meet the development needs of aluminum alloy wheel shape design.

3. Proposal of the parametric shape design system for automotive aluminum alloy wheels

When designing the shape of automobile aluminum alloy wheels, the parametric design method can better improve the efficiency of aluminum alloy wheel shape design. Therefore, a professional aluminum alloy wheel parameterized shape design system is established to enable designers to have a basis when designing aluminum alloy wheels. Followable. Based on the parametric design method, in view of the problems in the aluminum alloy wheel customization proposed above, an automotive aluminum alloy based on the knowledge of the aluminum alloy wheel structure, combined with the unit shape parameters of the aluminum alloy wheel, and computer-aided design as the core The framework of the parametric shape design system for wheels is expected to promote the further application of parametric design in the shape design of aluminum alloy wheels. The parametric shape design process of automobile aluminum alloy wheels is shown in Figure 1:

Fourth, the optimization countermeasures for the parametric shape design of automobile aluminum alloy wheels

After establishing the corresponding parameterized shape design system of automobile aluminum alloy wheels, the basic content of the parameterized shape design of aluminum alloy wheels is strengthened, and the unit shape parameters are managed to match the parameterized shape of aluminum alloy wheels with the shape of the whole vehicle, and improve the parameterization. The application value of design in the design of aluminum alloy wheels.

(1) Appearance parameters of aluminum alloy wheels

The structure of the aluminum alloy wheel hub includes seven parts: rim, offset, bead seat, rim, spoke, valve hole, and groove bottom. According to the shape, it is divided into three types: spoke type, disc type and mesh type. In addition to the standard parts, the aluminum alloy wheel shape design mainly considers two aspects: the layout and arrangement of the spokes of the front plate and the characteristics of the side-view spoke curve. The aluminum alloy wheel hub must be symmetrical to the center of concentric circles due to its functional and structural constraints, and the spokes are in a radial shape. The form of the front plate of the aluminum alloy wheel has the greatest influence on the overall shape of the aluminum alloy wheel. The research should first start with the form, composition and change characteristics of the front plate. Therefore, the shape of aluminum alloy wheels is mainly based on the study of the form characteristics of the front plate, and the side spoke curve characteristics are supplemented. The form characteristics of the side pieces of aluminum alloy wheels are mainly flat, concave and convex. Aluminum alloy wheels have to bear a certain pressure and have certain elasticity and toughness. Therefore, it is necessary to choose a suitable and well-stressed structure. The concave and convex forms are mostly used because of their stress structure, and the side is linear form because of the force. The structure is not ideal and fewer choices. The side modeling form is shown in Figure 2:

The design of the front face sheet of the aluminum alloy wheel hub shape needs to be studied with the theory of launching composition in the plane composition. The shape of the aluminum alloy wheel hub is studied from the perspective of the launch composition, that is, the spokes are equivalent to the basic shape or skeletal structure in the launch structure; and because the functional structure of the aluminum alloy wheel hub is limited, it must be in a concentric circle and there is only one launch center, so the launch structure is adopted. Centrifugal, centripetal, and concentric launch. After that, the mapping relationship between the changing form of the launch structure and the shape of the aluminum alloy wheel was established, and the shape design of the aluminum alloy wheel was analyzed theoretically, and the design method of the shape of the aluminum alloy wheel was rationally discussed. The following are the structural diagrams of the three forms of aluminum alloy wheels, as shown in Figure 3:

Reasonable combination of points, lines, surfaces and basic shapes and bone lines can not only harmonize the structure and shape of the aluminum alloy wheel, but also ensure that the shape of the aluminum alloy wheel meets the standard and the design is reasonable.

(2) Parametric graphics parameters

The parametric design method is added to the shape design of the aluminum alloy wheel, and the adjustment of parameters and logic is used to obtain a variety of design results, which can effectively stimulate the designer's inspiration, obtain a satisfactory initial design concept, and then deepen it to obtain the final product shape. When selecting the parametric unit shape, starting from the function and form, drawing inspiration from nature and life, a unique aluminum alloy wheel hub parametric form design style is formed. There are two sources of parametric unit shape. One is the geometric shape composed of basic elements such as points, lines, and surfaces, which are arranged and combined according to the composition principle to obtain a new figure, namely Euclidean geometric figure; the other is non-graphic The basic properties, the size and shape of the figure can be changed, all geometric elements can be deformed and the properties of the topological geometric figure are unchanged. The form of the unit form is divided into two-dimensional state and three-dimensional state. Different morphological characteristics can bring different feelings to people's vision and psychology. In this article, the parametric unit forms are composed of regular, rhythmic, and dynamic forms. From this, it can be summarized as two-dimensional regular structure, two-dimensional rhythmic structure, two-dimensional dynamic structure, three-dimensional regular structure, three-dimensional rhythmic structure, and three-dimensional dynamic structure.

The parametric software platform includes three major types of software, namely: data visualization software; data, shape and structure analysis software; modeling software, and its corresponding programming languages. The parametric design platform software is shown in Table 1:

(3) Application method in spokes

The parametric aluminum alloy wheel shape design is divided into the basic shape application of the spokes as a whole and the partial basic shape applications of the spokes in different styles and vehicle applications. Different application methods bring different visual effects. The following table shows the comparison between partial applications and overall applications as shown in Table 2:

(4) Rule matrix method

The various components of aluminum alloy wheels are relatively independent and related, so the "rule matrix" method is adopted to combine the parametric elements and parametric elements in the shape design of aluminum alloy wheels in accordance with certain rules, using both vertical and horizontal directions. The rule matrix table, intuitively express the logical relationship between various influencing factors. The specific arrangement is as follows, where A is Euclidean geometry, B is topological geometry, 1 is a two-dimensional regular structure, 2 is a two-dimensional rhythmic structure, 3 is a two-dimensional dynamic structure, and 4 is a three-dimensional rule The formula composition, 5 is the three-dimensional rhythmic composition, and 6 is the three-dimensional dynamic composition, as shown in Table 3:

(5) Application examples of parametric design of aluminum alloy wheels

The design process of aluminum alloy wheel shape under the influence of parametric design method includes five parts: selecting aluminum alloy wheel parameters according to vehicle characteristics, selecting parameterized graphic parameters, selecting application methods, generating shape, and adjusting parameters. In the case of this article, the appearance parameters of the aluminum alloy wheel hub select the concave centrifugal shape, and the parametric graphics select the combination of three-dimensional rhythmic composition and European basic geometry. The parameterized graphics are locally applied in the aluminum alloy wheel hub. The software selects rhino and the plug-in Grasshopper. Generate a parametric aluminum alloy wheel model according to restrictions, and adjust, render, and load the parameters in the model. The specific process of parametric shape design of aluminum alloy wheels is as follows:

1. Model selection and feature extraction

In the selected model in this case, the grid structure adopts a rhythmic change. In order to coordinate and match the shape of the parametric aluminum alloy wheel with the overall style of the car body, the characteristics of the grille structure are extracted and applied to the parametric shape design process of the aluminum alloy wheel, as shown in Figure 4.

2. Selection of aluminum alloy wheel parameters

For the selection of the appearance parameters of the aluminum alloy wheel, the side piece of the aluminum alloy wheel adopts a concave type with good mechanical performance, and the structure of the aluminum alloy wheel adopts a centrifugal type. Figure 5 shows the selection of appearance parameters of aluminum alloy wheels:

As a result, the area in the rule matrix is limited as shown in the gray area in Table 4. By using the rule matrix to define the area, the next parameter selection process can be simplified:

3. Selection of parameterized graphics parameters

The parameters of the parametric graphics are selected to combine the three-dimensional rhythmic form (5) with the European geometry (A). The parameter selection of parametric graphics is shown in Figure 6:

Therefore, the area in the rule matrix table is limited as shown in the yellow area in Table 5:

4. Application method

The parametric graphics adopts a local application method in the shape design of aluminum alloy wheels. The application method is shown in Figure 7:

Therefore, the area in the matrix of the team is limited as shown in the red area in Table 6:

5. Choose software

After the aluminum alloy wheel parameters, parameterized graphics parameters, and the combination method are selected, the application software is selected. The software in this paper selects the three-dimensional digital software Rhino and its plug-in Grasshopper. The software is shown in Figure 8:

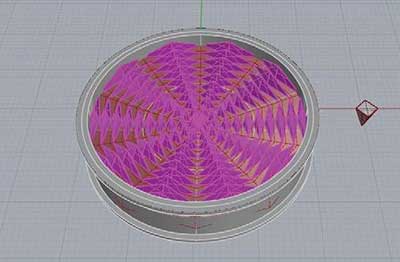

6. After the parameters of the generated model are limited, use modeling software to model the shape design of the parametric aluminum alloy wheel. The generated model is shown in Figure 9:

7. Adjust parameters

After the model is generated, adjust the battery parameters of the control parameters to make the model more in line with the design requirements. The adjustment parameter page is shown in Figure 10:

8. Final model

After the parameters are adjusted, the final model is obtained (Figure 11), which is then rendered (Figure 12), loaded into the vehicle (Figure 13), and the design is completed.

By establishing a corresponding parametric design system, the different design contents of the parametric shape of the aluminum alloy wheel are classified in detail, the parameters of the aluminum alloy wheel and the parametric graphic parameters are managed, and the parameters are limited by the rule matrix table, and the next step is the parameter selection It must provide an intuitive reference, improve the application value of parametric design in the shape design of aluminum alloy wheels, and promote the development of parameterization of aluminum alloy wheels. The above steps are the parametric aluminum alloy wheel shape design steps. In specific applications, attention should be paid to extracting the characteristics of the body shape to design the aluminum alloy wheel shape to make the shape of the aluminum alloy wheel more harmonious with the actual car model.

in conclusion

Parametric design methods have many advantages. It can not only apply data algorithms to the design process, but also enable perceptual design to have rational theoretical support, improve the designer's design efficiency, and form new design methods and ideas. Under the influence of consumers¡¯ increasing personalized demand, the parametric design method breaks the homogenization deadlock caused by mass production. By extracting elements from the car model for parametric shape design, it can not only satisfy consumers¡¯ unique aluminum alloy wheel shape Requirements, and can match the overall shape of the car. This article summarizes the application of parametric design of automotive aluminum alloy wheels, and discusses the parametric design system of aluminum alloy wheels. However, as part of the automobile, aluminum alloy wheels were born with the emergence of automobiles. The car models and styles are different, and the shape and structure of the matching aluminum alloy wheels are also different. When installing the car, choose the style, shape and color of the body. , The structurally matched aluminum alloy wheels make it truly realize the perfect combination of science and technology. However, because the parametric aluminum alloy wheel design has the characteristics of multidisciplinary integration and strong practicality, the system and combination method proposed in this paper still need industry practice and verification, and then adjust and optimize it.

JHM WHEELS JHM INC